What sectors we work for

Stamplef Ltd. is a major player in the cold sheet metal processing industry.

Automotive

household appliance

construction

photovoltaic

shelving

fixtures

Our services

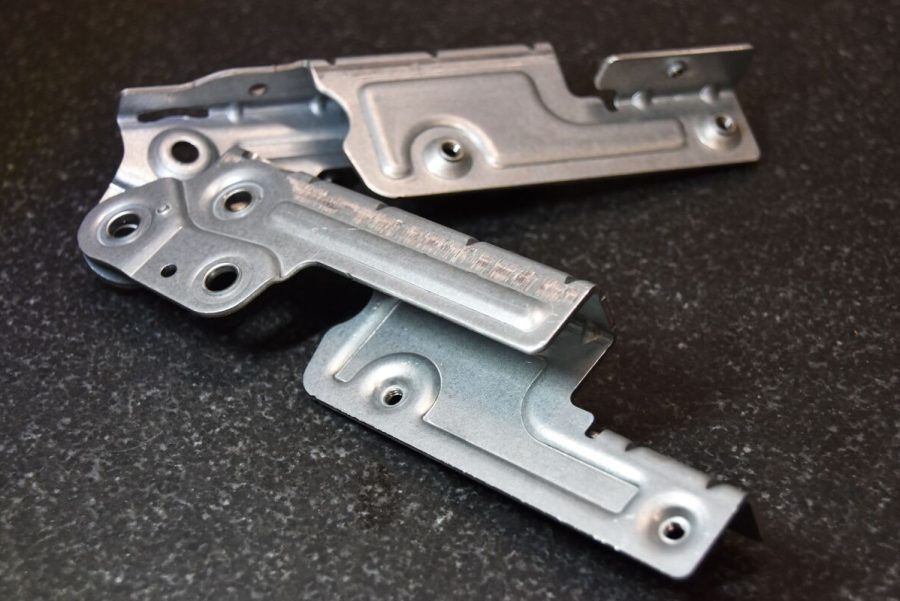

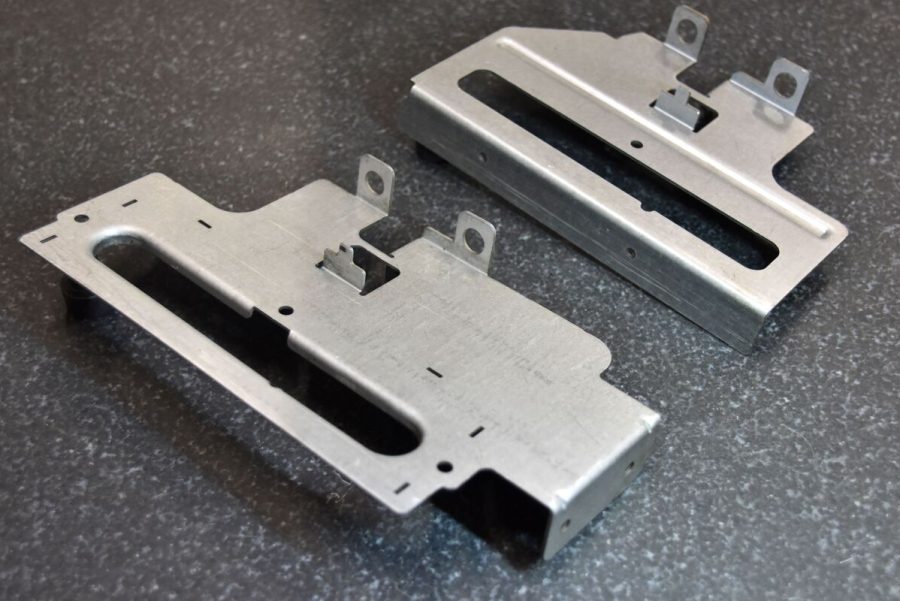

Sheet Metal Stamping and Blanking, Assembly, Bending and Wire Welding.

Our focus is to bring complete and technologically advanced solutions to the market from design, product development, testing, industrialization to production.

Design

Mold Creation-Maintenance

Cold metal stamping presses

Dimensional checks with 3d measuring machine

Who we are

Stamplef s.r.l. was founded in 1976 in Rossano Veneto.

The business is on a family basis and Mr. Bruno Carinato is the founder .

In the late 1980s his sons joined the company, and soon Stamplef s.a.s. became an organized and steadily expanding manufacturing operation.

With the acquisition of new customers comes the need for more production space and, the equipping of new machinery to better meet their needs . In 2009, the company moved to the industrial area in Castione Di Loria, to a new production facility, while maintaining the site in Rossano Veneto as its registered office and production unit, used for logistics and warehousing.

Our strengths

Our company has been in the sheet metal stamping business for more than 40 years, processing high-strength and deep stamping materials in the automotive, household appliance, construction, fixture parts, shelving and photovoltaic sectors.

Experience

40 years of experience in the industry, we boast large customers we have served as subcontractors

Quality

Quality materials, constantly updated machinery and passion for generations

Tailored

Constant innovations and expansions enable us to better meet customers' needs

What we accomplish

For the construction and/or maintenance of molds, we operate both in-house and with tooling companies, which are able to meet even the most demanding requirements with their mold design and construction capabilities.

In addition, if the molded part requires it, we can also perform assembly by continuous wire welding.

Contact us for your project

We guarantee professionalism and maximum availability and flexibility in all our achievements.